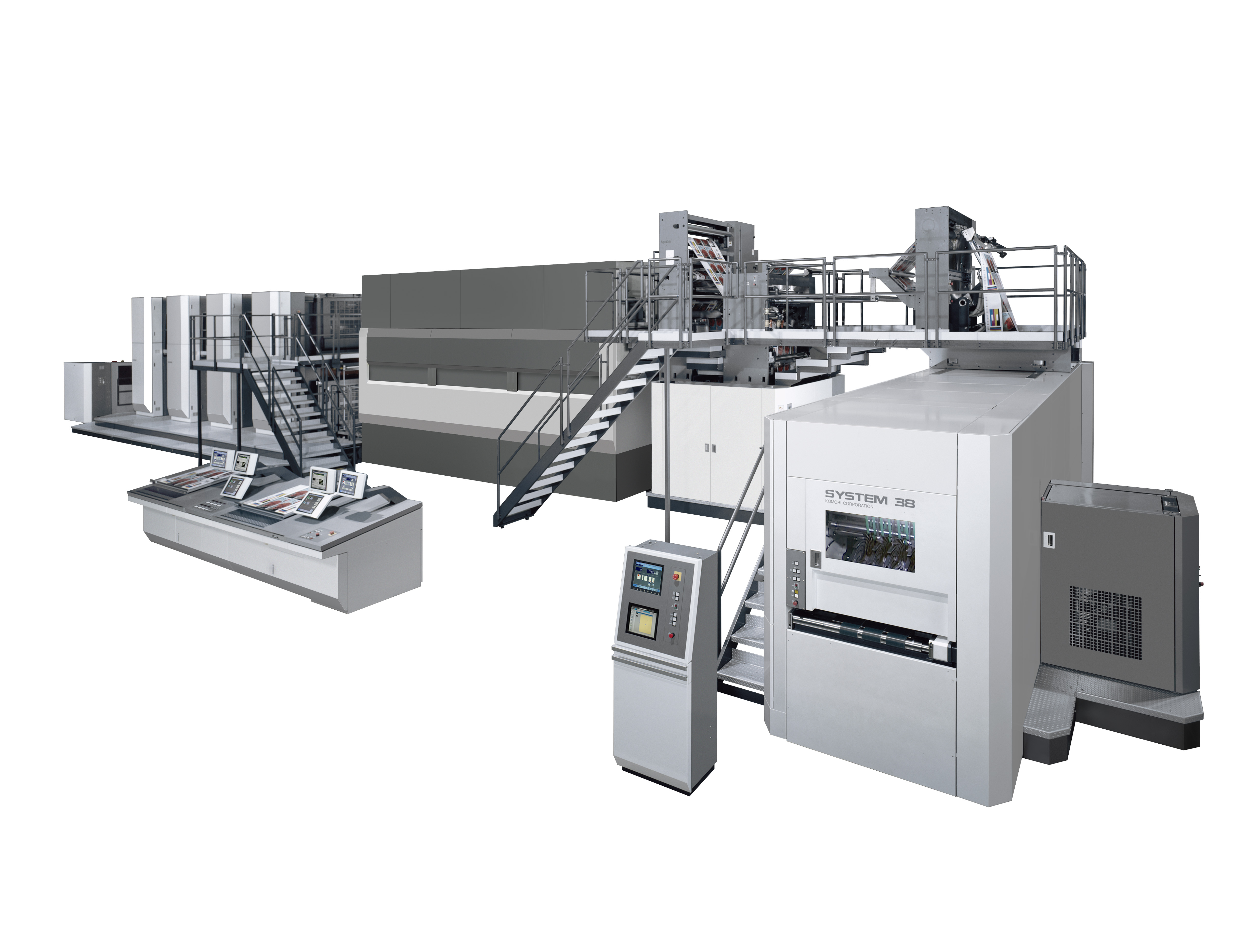

KOMORI SYSTEM 38D

Unrivaled quality, productivity and technology – every time.

- Fitted to your workflow - Designed from the ground up to fit into any CIP4/JDF-driven workflow

- High-speed, high performance - 40 000 iph maximum printing speed for high quality 32-page web print jobs, designed to fit any CIP4/JDF-driven workflow

- System-wide reliability - Enjoy the full support of an intelligent technical support system

Quality

The superior print quality of the System 38 press is an established fact. The key is Komori's unique cylinder array of double-size blanket and plate cylinders and large-diameter inking rollers, which guarantee an utterly stable, stress-free paper flow.

Productivity

Full Automatic Plate Change (APC) lets one operator change all eight plates in less than three minutes. The press is designed to maximize the efficiency of Full APC, with easy setting of plates in the loader and ample space between units for the operator.

Reliability

The System 38D features advanced self-diagnostics that permit rapid troubleshooting and maintenance control and provide an error history. Monitoring the press over the network allows for remote troubleshooting and support when required.

Komori DoNet-based KHS-AI system

System 38D productivity is derived from the logic of a 32-page press printing flawlessly at 40,000 iph. The imperative of handling shorter run lengths makes short makeready time equally important. Directing this brilliant performance is the Komori DoNet-based KHS-AI (Advanced Interface) system with integrated self-learning function, standard on the System 38D. K-Station sends the job ticket, including paper specifications, inking profile, and fold format to KHS-AI, which then searches its database for the optimum press operating parameters, controlling web guides, tensions, dryer settings and other variables.

FEATURES:

- High fold quality

- Innovative drying technologies

- Komori's unique cylinder array

- Constant Productivity